Wintech Supply is leading industrial boiler chimney manufacturers, suppliers in India and Delhi. We supply to international customers and also have upgrade and retrofit facilities. These provide turnkey services ranging from design to commissioning and after-sales service as well. These deal in industrial scrubbers, industrial chimneys, and bag filters. These deliver maximum performance to new as well as existing plants

About Industrial Boiler Chimney:

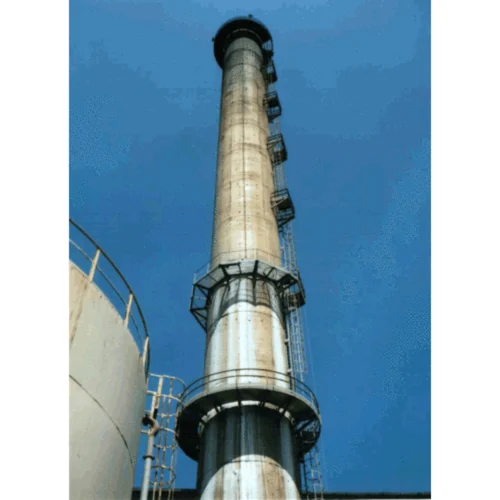

Industrial Boiler Chimney is a lot more than just a monolithic piece of equipment; it's the little-discussed, vital piece of equipment that enables smooth running, headache-free compliance with regulations, and protecting your entire industrial complex at low cost. Our specially designed chimneys are the last barrier of these gases, holding them suspended in the air safe from your staff and surrounding communities. We take pride in constructing chimneys not only strong and dependable but dispersion-optimized for fulfillment of the most stringent requirements of air pollution abatement.

Types of Industrial Boiler Chimney:

Being as well-established industrial boiler chimney manufacturers in India and Delhi, these are usually classified primarily according to building material and support load, the following are some of its types:

- Steel Stacks (Guyed or Self-Supporting): These are usually manufactured in the factory and then shipped and installed, and also proportional in size in relation to a broad spectrum of industrial sizes but need extra maintenance so These won't rust.

- Reinforced Concrete Chimneys: Because of our strength and very high resistance to endure harsh weather and earthquake situations, these are usually used in heavily large power plants and industrial complexes. These provide long life and additional stability.

- Brick Chimneys: Bricks are ancient and very resistant to corrosive and heat action of acidic flue gases. Dense and pleasant, these are used where special or historic architectural requirement exists, but very heavy and expensive for very tall buildings.

- Multi-Flue Chimneys: These are separate flues supported within a shared external casing. These are constructed in a way that exhaust can be treated from more than one different boiler or process separately, saving space and significantly bringing down the construction cost overall below that of separate chimneys.

- Fiberglass Reinforced Plastic (FRP) Chimneys: FRP chimneys are used only in corrosive exhaust gas industries and are highly chemical-resistant and lightweight. FRP chimneys are structure self-supported in nature or may be combined with steel support frames to offer additional stability.

Technical Specification of Industrial Boiler Chimney:

We have added below a technical sheet of industrial boiler chimney that provides more technical information such as:

| Feature / Parameter |

Specification Summary |

| Primary Function |

Disperse flue gases safely; ensure low ground-level pollution. |

| Design Standards |

IS 6533, IS 11504, IS 4998, CPCB norms (India-specific). |

| Construction Type |

Self-supported (steel/concrete), Multi-flue common for larger plants. |

| Height & Diameter |

Based on dispersion modeling (AERMOD), flue gas volume, exit velocity. |

| Liner Material |

Borosilicate glass, acid-resistant brick, SS alloys (for corrosion/acid). |

| Insulation |

Mineral wool/ceramic fiber to prevent condensation and heat loss. |

| Outer Shell Material |

Carbon steel (coated) or Reinforced Concrete (RCC). |

| Structural Design |

Withstands wind (IS 875 Part 3) and seismic (IS 1893) loads. |

| Ancillary Components |

Aviation lights, CEMS ports, access ladders, lightning protection. |

| Monitoring |

CEMS (Continuous Emission Monitoring Systems) for compliance. |

Benefits of Industrial Boiler Chimney:

As Industrial boiler chimney suppliers in India and Delhi, these are a component of contemporary industrial process, possessing massive advantages and extensive application as follow:

- Flue Gas Discharge: Flue gases, hot and potentially hazardous, laden with pollutants, are emitted by chimneys elevated in the air in a harmless and safe way, safeguarding plant staff and local residents from exposure.

- Environmental Control & Dispersion: By formation of exhaust plume rise, chimneys allow for more efficient dispersion of pollutants, greatly reducing ground level concentrations and deterring industries from violating tighter national and international standards of air quality requirements.

- Improved Boiler Efficiency (Natural Draft): Efficient chimney forms a natural draft which pulls the combustion air into the boiler and expels the flue gases outwards. It increases combustion efficiency, conserves energy, and improves overall boiler efficiency.

- Protection against Corrosion: Removal of hot corrosive gas avoids direct contact with internal boiler hardware and ducts, minimizing corrosion risk and need for frequent, repeated replacement of costly boiler systems.

- Noise Control & Aesthetic Architecture: Acoustic dampening materials can be utilized to design damped exhaust boiler noise chimneys. Our structural role can be utilized to silence visual impact or act as a marker for an industrial complex.

Applications of Industrial Boiler Chimney:

Serve as well-established industrial boiler chimney suppliers in India and Delhi, it is applicable in different sites as follow,

- Power Generation Plants: Utilized for gas of coal-fired, gas-fired, and biomass power generation plants for secure dispersion and acceptability for mass-scale power generation regulation.

- Chemical and Petrochemical Processes: Used for burning various metals of process gases, and also burning residues, where, in some cases, special lining material has to be used to treat corrosive or reactive flue streams.

- Manufacturing and Process Plants: Used in the majority of the process and manufacturing plants such as cement, steel, textiles, food processing, and pulp & paper in which boilers are used to generate steam to supply heat for drying, heating, and other process uses.

- Waste-to-Energy Plants: Venting incinerator furnace gases utilized to burn industrial or municipal waste to generate energy, controlling emissions of advanced burning process of waste.

- Heating, Ventilation, and Air Conditioning (HVAC) Systems: Central heating facilities are installed in commercial and institutional buildings to support industrial boiler chimneys for mere venting boiler combustion exhaust.

Wintech Supply is prominent industrial boiler chimney Manufacturers, Suppliers in India and Delhi. From its deliberate construction and material choice to its deliberate location and massive construction, every element within a chimney is serving in its unassuming function of transferring impurities, safeguarding equipment from corrosive vapors, and providing the perfect draft for combustion. With businesses all over competing with each other on the green and clean path of business, the perfection and superior performance engineering of the industrial chimney are a bare requirement in being as environmentally friendly as humanly possible and achieving maximum productivity and lifespan of industrial installations. Contact us now!